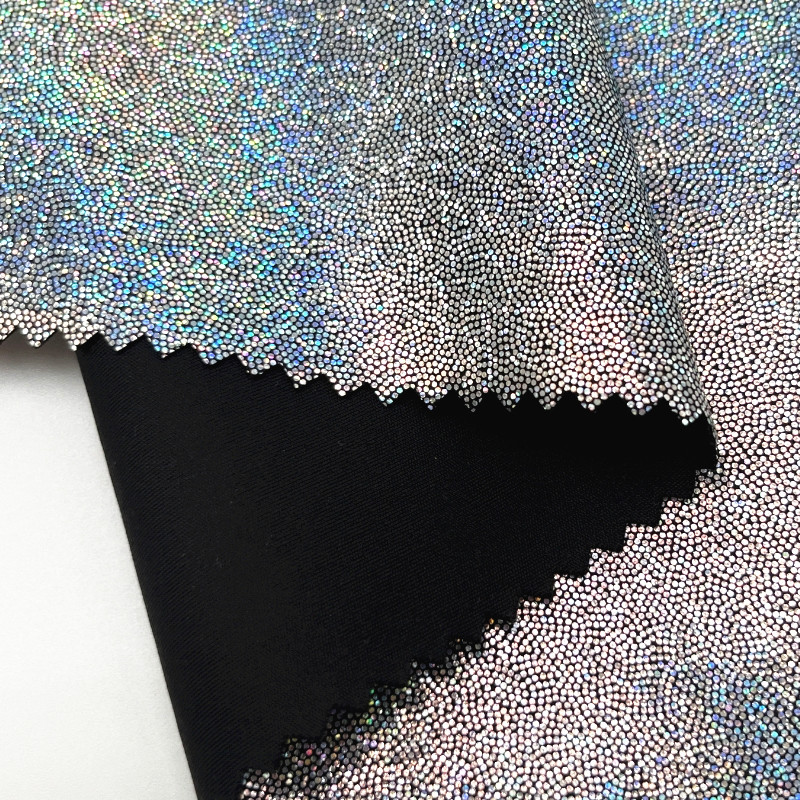

Knitted printed fabric is a type of fabric where printing techniques are applied to knitted textiles during the manufacturing process. Knitted fabrics are created by interlocking yarns, providing them with greater softness and elasticity compared to woven fabrics. Printing involves adding patterns or colors onto the surface of the fabric, and common printing techniques include digital printing, screen printing, and heat transfer.

The process of making knitted printed fabric typically involves the following steps:

- Fabric Selection: Choose suitable knitted fabrics for printing, such as cotton, polyester, or blends.

- Design Preparation: Designers create or select patterns or images suitable for printing.

- Printing Preparation: Prepare necessary colors and tools according to the design. Different printing techniques require specific preparation steps.

- Printing Operation:

- Digital Printing: Use computer-controlled printers to directly print designs onto the fabric.

- Screen Printing: Cover the design on a stretched screen and then transfer ink through the screen onto the fabric.

- Heat Transfer: Print the design onto special transfer paper and then transfer the pattern onto the fabric using heat and pressure.

- Color Fixation and Finishing: After printing, the fabric needs to undergo color fixing to ensure the patterns adhere securely to the fabric. Additionally, it require post-processing steps such as washing or drying.

Knitted printed fabrics use in garments, home textiles, and decorations. It offering a wide range of pattern and color options suitable for products that require softness and comfort.

Knitted printed fabrics are available in various fibers such as cotton, polyester, nylon, modal, etc., depending on the desired texture, functionality, and end-use. The design is creat or edited using computer software to ensure accuracy and quality.

To prepare for printing, colors are mixed according to the design requirements. And printing tools are selected based on the chosen technique (digital, screen, heat transfer). The chosen technique will dictate the specifics of the printing process, whether it involves direct printing (digital), ink transfer through a screen (screen printing), or heat transfer from a special paper (heat transfer).

After printing, the fabric undergoes a color fixation process to ensure the patterns remain vibrant and durable. This may involve heat setting, steam processing, or chemical treatments. Post-processing steps like washing or drying may also be necessary to enhance the fabric’s comfort and quality.

Knitted printed fabrics are used extensively in apparel production, home furnishings, and decorative items due to their versatility, softness, and ability to showcase intricate designs and vibrant colors.